Drilling

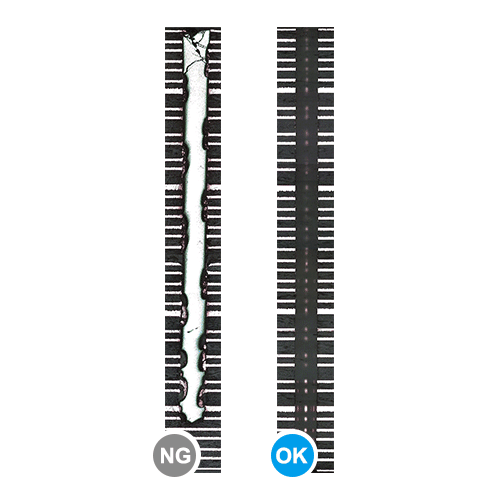

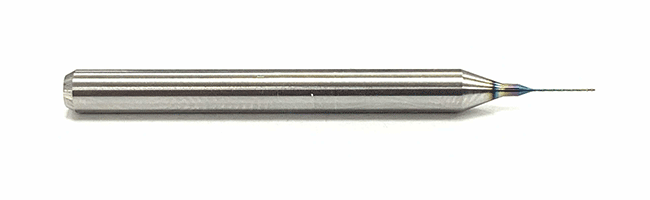

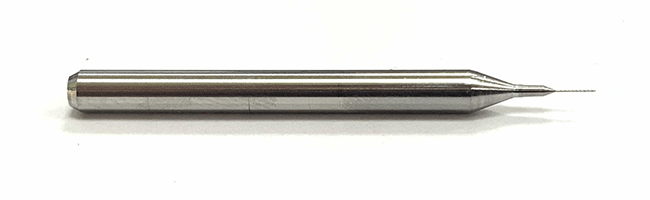

High aspect radio with coating bit

Drill bit with coating for super-thick multi-layered PCBs enhance the chip removing capacity.

| Type | Diamter | Length | Aspect ratio |

|---|---|---|---|

| UC | 0.20 | 5.5 | 27.5 |

| UC | 0.225 | 5.5 | 24.5 |

| UC | 0.25 | 7.0 | 28.0 |

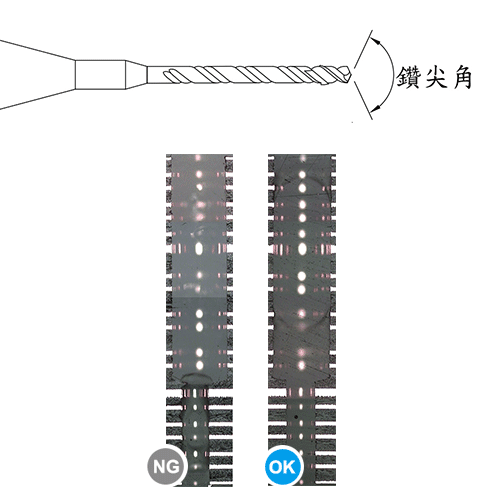

Backdrilling(Counterboring)

Drill bit designed with a point angle of 150° or 165° will not only enhance the chip removing capacity but reduce the burr problems. This kind of drills have good performances on back drilling & blind drilling.

| Type | Diamter | Length |

|---|---|---|

| UC | 0.30 ~ 0.70 | 5.0 |

| UC | 0.50 ~ 1.15 | 7.0 |

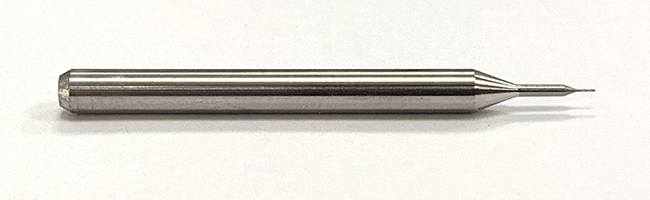

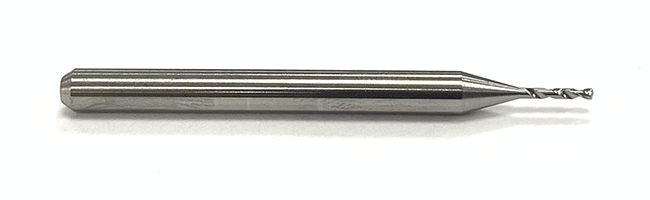

Pre drilling and positioning drilling

Positioning pins ar are designed to enhance the accuracy of high aspect ratio drills.

| Type | Diamter | Length |

|---|---|---|

| UC | 0.20 | 1.0 |

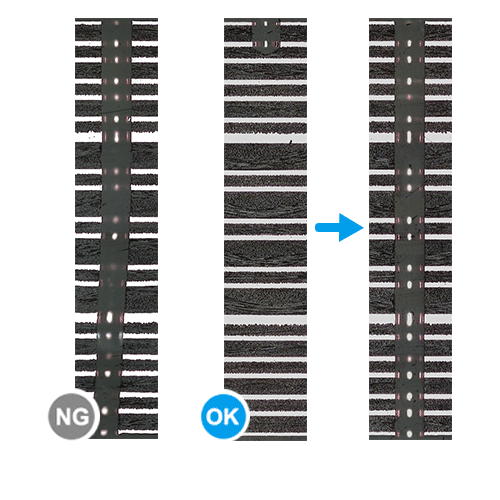

Slot bit

Used for Z-axis cutting machining on drilling machines. The geometrical design along with the high rigidity improves bad slot problems and gives better slot quality.

| Type | Diamter | Length |

|---|---|---|

| SD 、 USD | 0.40 ~ 0.55 | 4.7、5.5 |

| USD | 0.60 ~ 1.00 | 4.7 |

| USD | 0.70 ~ 1.65 | 6.7 |

| SD | 0.60 ~ 1.25 | 5.7、6.7 |

| SD | 0.70 ~ 3.00 | 8.7 |

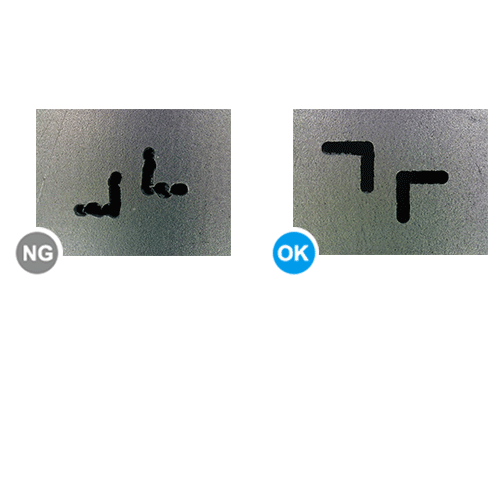

For ABF Application

When being used on the build-up PCB, drills designed with parallel flute and coating can improve bad chip-removig and enhance the accuracy.

| Type | Diamter | Length |

|---|---|---|

| ST 、 UC | 0.15 | 3.5 |

| ST 、 UC | 0.20 | 4.3 |

For HDI & Automobile Application

HDI: High rigidity designs not only give better hole accuracy, but satisfy the in-hole quality requirement

from customers.

Automobile: The design of good chip-removing capability can give better hole quality.

| Type | Diamter | Length |

|---|---|---|

| UC | 0.20 | 3.6、4.0 |

| UC | 0.25 | 4.0、5.0 |

| UC | 0.275 | 4.5、5.5 |

| UC | 0.30 | 5.0、6.2 |

| UC | 0.35 | 5.5、6.5 |

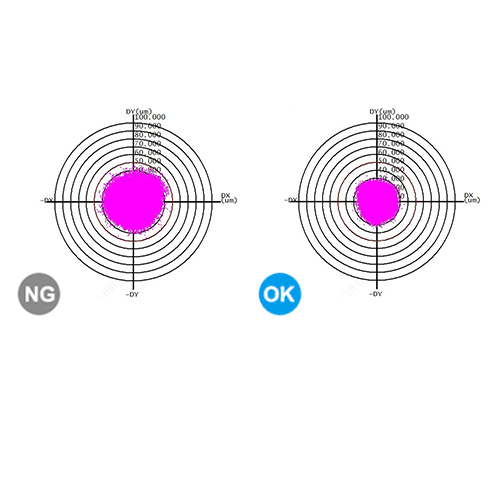

For BGA Application

For Dense-hole PCB and increase stack demands, intensive drill design with chip removing coating can give the accuracy which meets customer standards.

| Type | Diamter | Length |

|---|---|---|

| ST 、 UC | 0.10 | 1.8、2.0 |

| ST 、 UC | 0.15 | 2.7、 3.0、3.5 |

For FPCB & RF Application

Products, specifically designed for FPCB, have good performances on improving hole quality, PP

surface protrusion, nodules and corner cracking.

| Type | Diamter | Length |

|---|---|---|

| ST 、 UC | 0.11 | 1.8、2.0 |

| ST 、 UC | 0.15 | 2.5、2.7、3.0 |

Coating Tool

| Coating | Color | Thickness | Range | Function | |

|---|---|---|---|---|---|

| ta-C |  |

Rainbow | 200~300nm | 0.075~0.25mm | best chip-removing capability, higher unit price |

| DLC |  |

Grey blue | 200~300nm | 0.10~0.25mm | good chip-removing capability |

| ZrN |  |

Fuchsia | 200~300nm | 0.10~0.25mm | hole quality enhancement |

| AICrN |   |

Silver | 400~500nm | 0.20~0.35mm | good wear resistance |

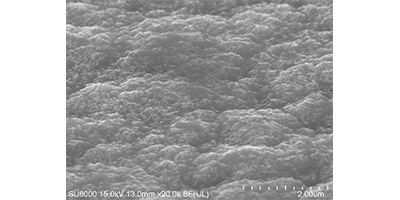

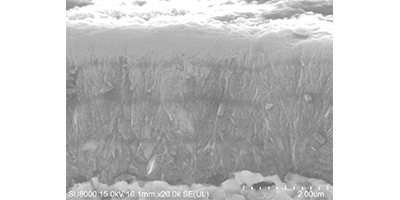

CVD Diamond Coating

|

||

|

|

|